S M T

Manufacturing Capability

1. Full process workshop, Coordinated Process

- Materials Purchasing

- SMT

- After welding

- Assembly

- Testing

- Inspection

2. Small amount of diversity, Satisfy all kind of customer order

- Trial

- Pilot Run

- Batch Production

- Mass Production

3. Capability

- SMT: 5 Million components/day

- DIP:100 thousand components/day

- 3 shift

Production Type

In recent years , one of the great development of industrial circle is the rise of outsourcing , it has already generally existed in every profession and trade now.To decrease the cost and increase the competitiveness , a lot of enterprises even only leave the nuclear business inside , others are all belonged outsourcing. In other words , good at using the outsourcing method that has been only one effective means of enterprise's competition in the 21st century. MBC technology now is combining a integral service and good suppliers as the key advantage , we should become your best cooperative partner of a science and technology industry.

Following listed currently MBC's main production types :

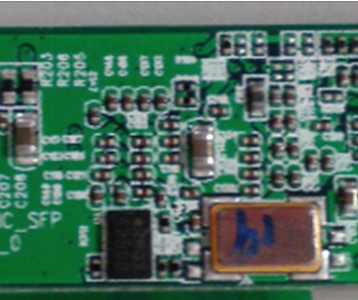

Photoelectric industry

- Digit camera product

- DVD display device control main board

- TFT LCD main board

Computer information industry

- Notebook main board

- Peripheral interface card of computer system

(EX: Interface card of video-information; result card of the sound ; power board.) - The computer fan's process and assembly

Communication industry

- Global position system

- Mobile telephone main board

Others industry

- Sound appliances

- Electronic information tests the tool type

Equipments

- SMT high speed line 4 Lines

3 eight hour shifts with the capacity of 5 million R、C chip mounting.

(SONY G-200*3、E-1000*1、E-1100*2;JUKI2050L*1、2050*2、

2060+Auto Try*3、3020*1) - ETC Reflow Soldering Oven :

8 sections of Reflow Soldering Oven 3 Sets

12 sections of Reflow Soldering Oven 1 Set - Wen-Hui GERBER program transferring software 1 Set

- AOI Auto Optical Inspector 1 Set

- Tin paste mixing machine :

with lead 1 Set

lead-free 1 Set - Auto tin paste printing machine 1 Set

- Spectrum Analyser (2.6Ghz~8.5Ghz) 5 sets

- Singal Generator ----- 5 sets

- Electronic Wire Shielded Room 2 Sets

- Manual Soldering and Assembling Production Line on final process section:

2 lines with lead, 2 lines with lead-free - Digital Oscilloscope 6sets

- Auto gluing machine with two liquid type by digital control 1 set

- Desktop Auto gluing machine with one liquid type 3 sets

- 20K Hz Supersonic press machine 1 set

- Dust alleviation room 2 sets

- Burn-in room 2 sets

- PCB cutting machine 1 set

Services

Service Items

- Double side SMT : MBC input SMT's manufacture already had good producing experience to derive out the steady and elastic production system ,we had professional engineering department to do CAM procedure since customer provides the data , therefore, we can provide the flexible service that within 4 hours to accomplish the production preparation, cooperating with complete production system to assign the capability in time , then achieve and safisfy customer's delivery.

- Since assembly , test , all production thru outscoucing processed through shipment were became a trend of a lot of enterprises did. Most evaluations to subcontract suppliers were focused on quality , delivery , price , while MBC not only pay attention to above 3 points competitiveness , also provided complete engineering capability to satisfy whole production produced. From initial customer' s data releasing to production operation set to final technical issues or new production research confirmed with customer's engineers , MBC all can handle up these successional step services.

- First article sample and small quantity production service : In view of RD personnel will require product qualification before move forward with the mass production , mostly will have low volume , tight delivery and lots of engineering demands and so on characters , MBC can offer customer to test-manufacture and small quantization produce , our key advantage is as following :

- Offering material and process , MBC's purchase resource can overcome the difficulty that low volume not easy to acquire the material.

- Accomplishing on line preparation within 4 hours , MBC's engineering resource can integrate all the date that production needs to avoid the unidentified information problem occurred on the production line.

- Test-manufacture and small volume production , MBC's production and management can assign the capability rescouce and commit customer the delivery on time.

- For test-manufacture type to provide the reports of ahead of production and after production , MBC's production and management systme have the meeting of ahead of production and after production to offer customer a test-manufacture relative information and do a mass production analysis on the future.

- The elastic and professional delivery service , MBC can deliver the goods to customer's hand at shortest time , will let you get rid of the test-manufacture is a nightmare imagination.

- No-clean Wave solder process , DIP plug in wave solder process or manual welding solder procee :Quality and delivery are the puzzlement of all the outscorcing enterprises , while most of process houses focused on how to improve SMT's production quality and capability , MBC also paid attention to traditional welding relative quality equally , so can offer same quality and delivery of SMT.

- others Value-added Service

- The design , solution of Print Circuit Board's Layout.

- The process and prototype build of Print Circuit Board.

- The design of industrial and mechanical.

Value-added Service

MBC has succeeded in developing the elasticity of outsourcing special offer service system , can put forward the most effective solution by customer's demand.

- The design , solution of Print Circuit Board's Layout. :

With abundant practice experience , MBC offers the proposal specially to coach customer solve the PCB Layout may occur any conditions , avoid EMI and process production may involve any problems. - The process and prototype build of Print Circuit Board :

Before the mass production , MBC's complete、 professional of prototype build service has channelled into the production's qualitification flow , to let you from sample、 polit run through mass production can put in one step. - The design of industrial and mechanical : MBC has integrated the capability of the industrial and mechanical's design , from appearance's design to plastic model produce that all have abundant experience , matching with a long-term cooperative insert modeling houses to offer the most economical and practice design demand to customer.

- Providing electronic products's whole production and special offer to customer.

The design of Print Circuit Board's Layout

Prototype build of test-manufacture

Purchasing the material for customer

Model or testing fixture's production

Mass production

12F-2, No. 102, Zhongping Rd.,TaoYuan City, TaoYuan County 33066, Taiwan (R.O.C.)

12F-2, No. 102, Zhongping Rd.,TaoYuan City, TaoYuan County 33066, Taiwan (R.O.C.) (03) 220-3118

(03) 220-3118 (03) 220-3116

(03) 220-3116